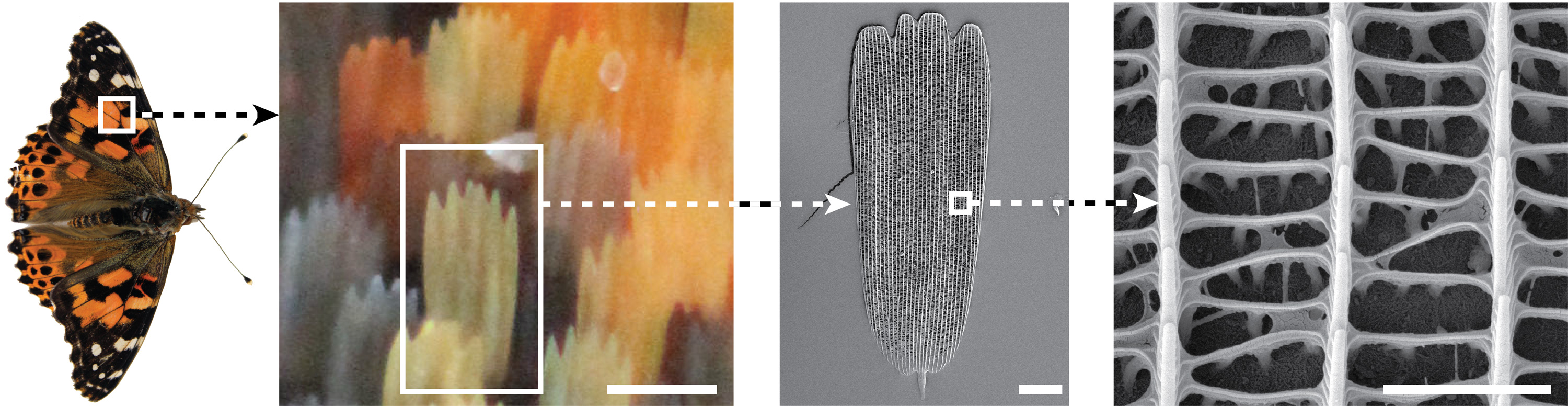

A butterfly’s wing is covered in hundreds of thousands of tiny scales like miniature shingles on a paper-thin roof. A single scale is as small as a speck of dust yet surprisingly complex, with a corrugated surface of ridges that help to wick away water, manage heat, and reflect light to give a butterfly its signature shimmer.

MIT researchers have now captured the initial moments during a butterfly’s metamorphosis, as an individual scale begins to develop this ridged pattern. The researchers used advanced imaging techniques to observe the microscopic features on a developing wing, while the butterfly transformed in its chrysalis.

The team continuously imaged individual scales as they grew out from the wing’s membrane. These images reveal for the first time how a scale’s initially smooth surface begins to wrinkle to form microscopic, parallel undulations. The ripple-like structures eventually grow into finely patterned ridges, which define the functions of an adult scale.

The researchers found that the scale’s transition to a corrugated surface is likely a result of “buckling” — a general mechanism that describes how a smooth surface wrinkles as it grows within a confined space.

“Buckling is an instability, something that we usually don’t want to happen as engineers,” says Mathias Kolle, associate professor of mechanical engineering at MIT. “But in this context, the organism uses buckling to initiate the growth of these intricate, functional structures.”

The team is working to visualize more stages of butterfly wing growth in hopes of revealing clues to how they might design advanced functional materials in the future.

“Given the multifunctionality of butterfly scales, we hope to understand and emulate these processes, with the aim of sustainably designing and fabricating new functional materials. These materials would exhibit tailored optical, thermal, chemical, and mechanical properties for textiles, building surfaces, vehicles — really, for generally any surface that needs to exhibit characteristics that depend on its micro- and nanoscale structure,” Kolle adds.

The team has published their results in a study appearing today in the journal Cell Reports Physical Science. The study’s co-authors include first author and former MIT postdoc Jan Totz, joint first author and postdoc Anthony McDougal, graduate student Leonie Wagner, former postdoc Sungsam Kang, professor of mechanical engineering and biomedical engineering Peter So, professor of mathematics Jörn Dunkel, and professor of material physics and chemistry Bodo Wilts of the University of Salzburg.

A live transformation

In 2021, McDougal, Kolle and their colleagues developed an approach to continuously capture microscopic details of wing growth in a butterfly during its metamorphosis. Their method involved carefully cutting through the insect’s paper-thin chrysalis and peeling away a small square of cuticle to reveal the wing’s growing membrane. They placed a small glass slide over the exposed area, then used a microscope technique developed by team member Peter So to capture continuous images of scales as they grew out of the wing membrane.

They applied the method to observe Vanessa cardui, a butterfly commonly known as a Painted Lady, which the team chose for its scale architecture, which is common to most lepidopteran species. They observed that Painted Lady scales grew along a wing membrane in precise, overlapping rows, like shingles on a rooftop. Those images provided scientists with the most continuous visualization of live butterfly wing scale growth at the microscale to date.

Image: Courtesy of the researchers

In their new study, the team used the same approach to focus on a specific time window during scale development, to capture the initial formation of the finely structured ridges that run along a single scale in a living butterfly. Scientists know that these ridges, which run parallel to each other along the length of a single scale, like stripes in a patch of corduroy, enable many of the functions of the wing scales.

Since little is known about how these ridges are formed, the MIT team aimed to record the continuous formation of ridges in a live, developing butterfly, and decipher the organism’s ridge formation mechanisms.

“We watched the wing develop over 10 days, and got thousands of measurements of how the surfaces of scales changed on a single butterfly,” McDougal says. “We could see that early on, the surface is quite flat. As the butterfly grows, the surface begins to pop up a little bit, and then at around 41 percent of development, we see this very regular pattern of completely popped up protoridges. This whole process happens over about five hours and lays the structural foundation for the subsequent expression of patterned ridges.”

Pinned down

What might be causing the initial ridges to pop up in precise alignment? The researchers suspected that buckling might be at play. Buckling is a mechanical process by which a material bows in on itself as it is subjected to compressive forces. For instance, an empty soda can buckles when squeezed from the top, down. A material can also buckle as it grows, if it is constrained, or pinned in place.

Scientists have noted that, as the cell membrane of a butterfly’s scale grows, it is effectively pinned in certain places by actin bundles — long filaments that run under the growing membrane and act as a scaffold to support the scale as it takes shape. Scientists have hypothesized that actin bundles constrain a growing membrane, similar to ropes around an inflating hot air balloon. As the butterfly’s wing scale grows, they proposed, it would bulge out between the underlying actin filaments, buckling in a way that forms a scale’s initial, parallel ridges.

To test this idea, the MIT team looked to a theoretical model that describes the general mechanics of buckling. They incorporated image data into the model, such as measurements of a scale membrane’s height at various early stages of development, and various spacings of actin bundles across a growing membrane. They then ran the model forward in time to see whether its underlying principles of mechanical buckling would produce the same ridge patterns that the team observed in the actual butterfly.

“With this modeling, we showed that we could go from a flat surface to a more undulating surface,” Kolle says. “In terms of mechanics, this indicates that buckling of the membrane is very likely what’s initiating the formation of these amazingly ordered ridges.”

“We want to learn from nature, not only how these materials function, but also how they’re formed,” McDougal says. “If you want to for instance make a wrinkled surface, which is useful for a variety of applications, this gives you two really easy knobs to tune, to tailor how those surfaces are wrinkled. You could either change the spacing of where that material is pinned, or you could change the amount of material that you grow between the pinned sections. And we saw that the butterfly is using both of these strategies.”

This research was supported in part by the National Science Foundation, the Humboldt Foundation, and the Alfred P. Sloan Foundation.