If you’re a designer, you probably know that creating stunning typography can be a time-consuming and, at times, challenging task. But what if I told you that you could achieve typographical works of art with just a click of a button? That’s where Photoshop layer styles come in handy.

Photoshop layer styles are pre-configured commands that you can apply to any text layer in Photoshop to create stunning text effects in no time. Whether you’re looking for a metallic, neon, or grunge effect, these layer styles have you covered.

The best part is that you don’t have to be a Photoshop expert to use them. Applying these effects is as simple as clicking a single button, so you can save time and energy while still creating professional-looking typography.

While there are many Photoshop text effect tutorials, the quickest and easiest way to achieve beautiful text effects is to download one of the free Photoshop layer styles available online. So why not give it a try? Download one of the free Photoshop layer styles we have for you below and take your typography game to the next level!

You might also like our premium collection of layer styles for Photoshop. And, as for text effect tutorials, we have those for Photoshop, Illustrator, and After Effects.

Free to Download

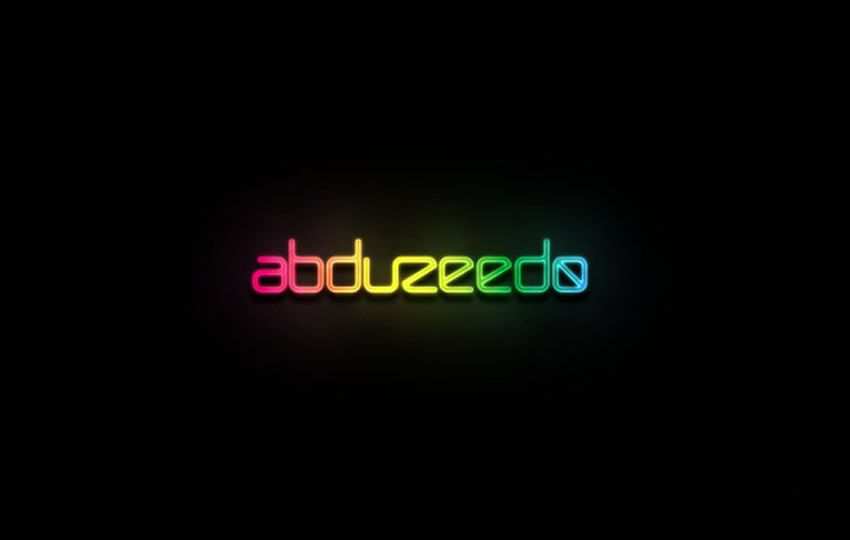

With this free PSD template, you can convert regular text into a modern, colorful, and stunning typographical style, giving you a unique and fun effect.

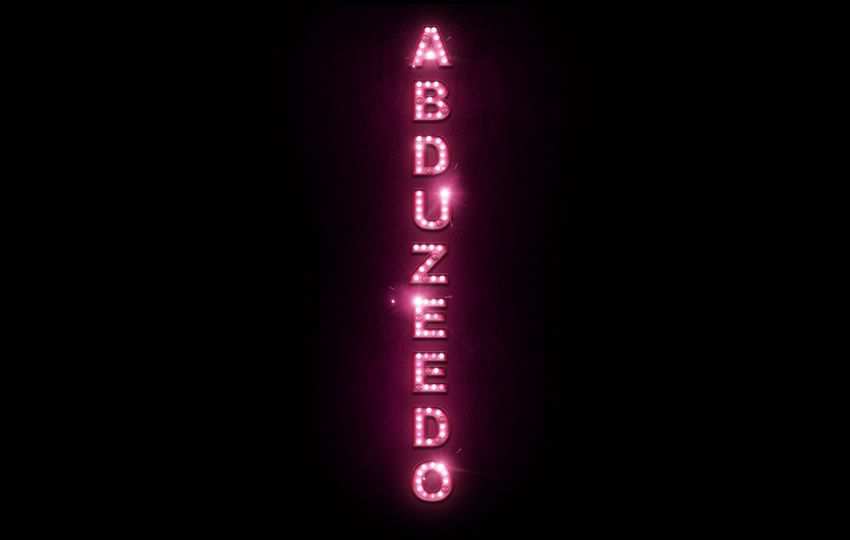

Thanks to this pack of Photoshop layer styles, you can instantly transform any text into 80’s style typography. The package contains 18 different styles.

Free to Download

Use this layer style to give any text a video game-style appearance. The article will walk you through the exact steps necessary to reproduce this effect, and you can even download the Photoshop file to follow along.

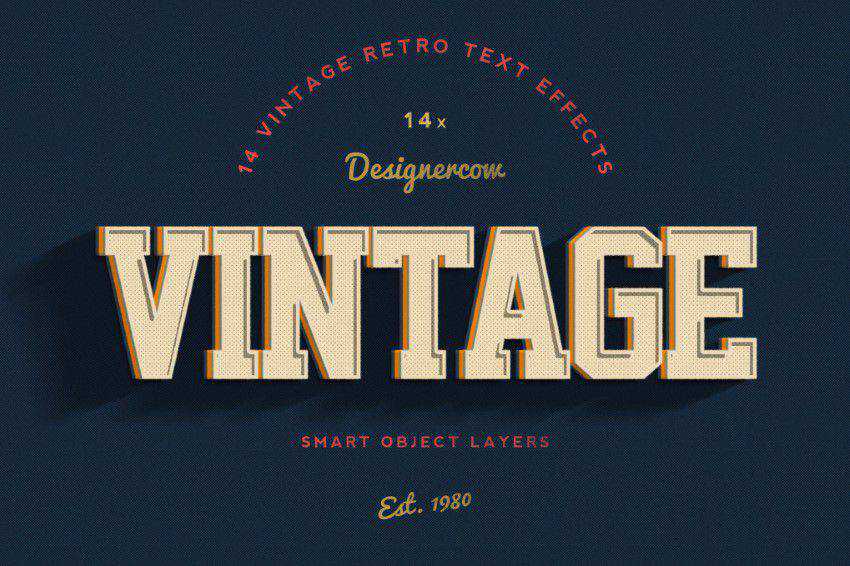

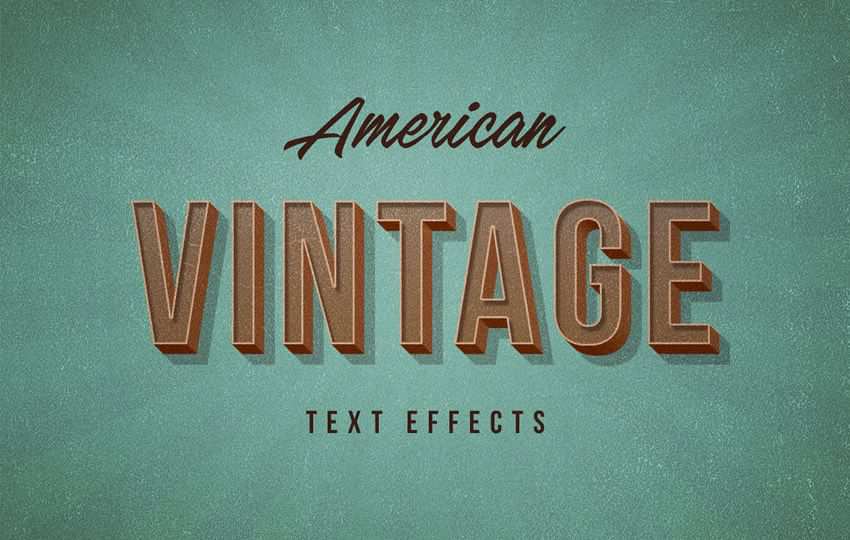

With this layer styles pack, you’ll be able to go back in time and make any text appear vintage. The package contains 18 layer styles.

Free to Download

This free PSD template is a realistic chalk lettering text effect that will transform your text into stunning hand-written typography on a chalkboard.

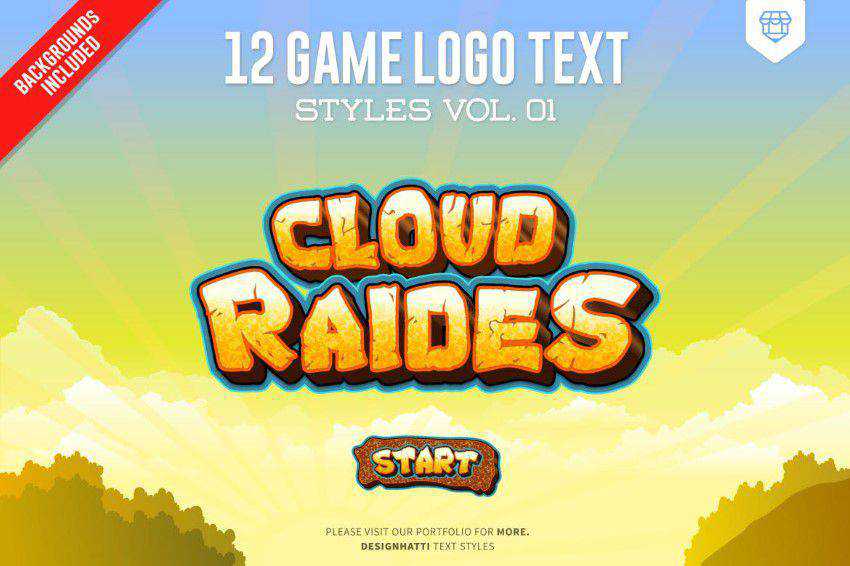

Give your text a more playful appearance resembling video game titles with this layer styles pack.

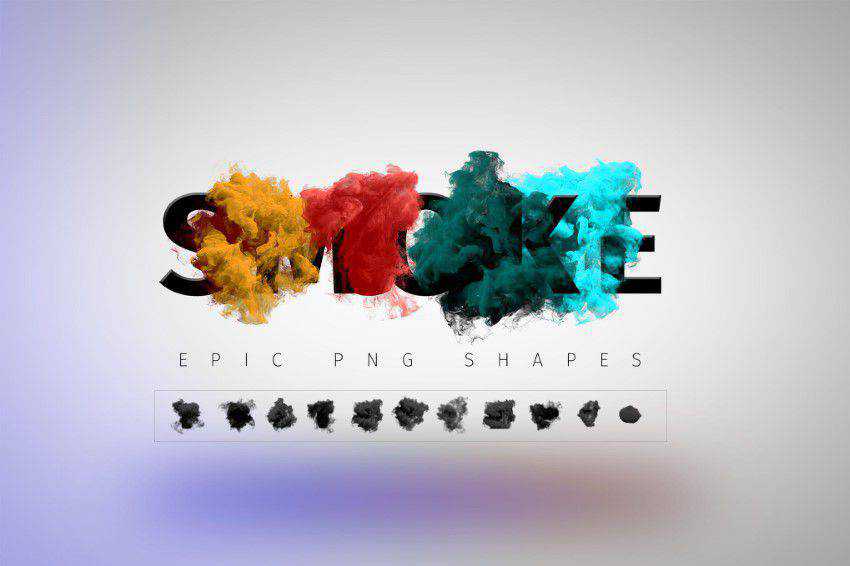

Use this layer styles pack to make your text smokier. The package contains 11 different smoke effects.

Free to Download

Following the original aesthetics of the hugely popular TV show, this free Photoshop text style perfectly captures the ambiance and mood of Stranger Things.

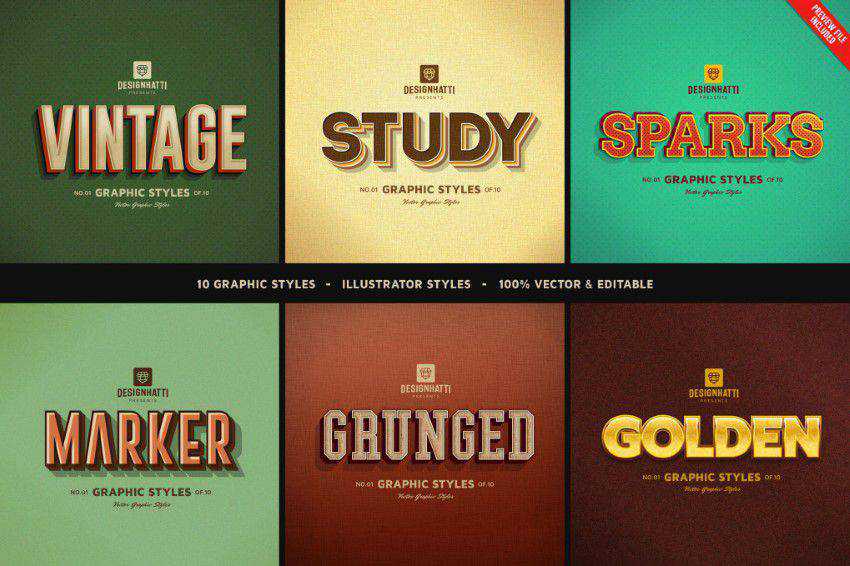

Add a touch of retro style to your text with this retro vintage styles pack for Photoshop. The package includes ten different styles.

Free to Download

These free Photoshop text styles perfectly embody old Hollowood movies, retro ad posters, and those vintage street signs from the 1930s, 40s, and 50s.

Free to Download

Make your text glow in the dark with the help of this layer styles pack. The tutorial will walk you through the steps necessary to achieve this effect, and you can download the Photoshop file to follow along.

Free to Download

This free PSD template is bundled with three vintage text effects (and photo effects) that are the embodiment of good taste and simplicity.

Free to Download

With this free 3D Photoshop text effect, you can add depth and a sandwich texture to your plain text. Type your text in the smart layer and save the changes.

Free to Download

To apply this letterpress effect, type your text and apply the style from the Styles palette. It’s super simple.

Free to Download

Use this tutorial to learn how to create casino-style text in Photoshop. As usual, the tutorial includes the Photoshop file so you can easily follow along.

Free to Download

Open the smart object, type in your text, and apply the changes. You will quickly have a fun wood-style typographical effect.

Free to Download

Double-click the smart-object layer and add your own text or graphic. You can also change the background color, text color, and 3D depth color.

Free to Download

With the help of this layer styles pack, you will instantly give your text a metallic look and feel.

How to Install & Use Layer Styles in Photoshop

Here’s a straightforward guide on how to install and use layer styles:

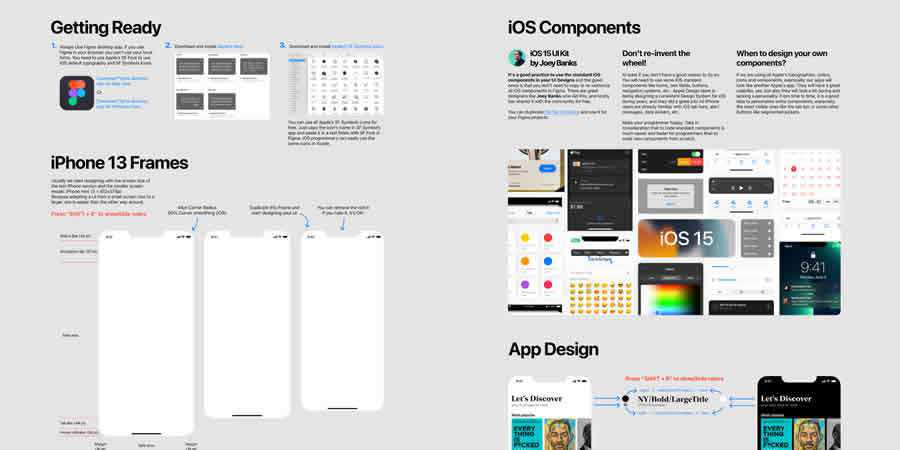

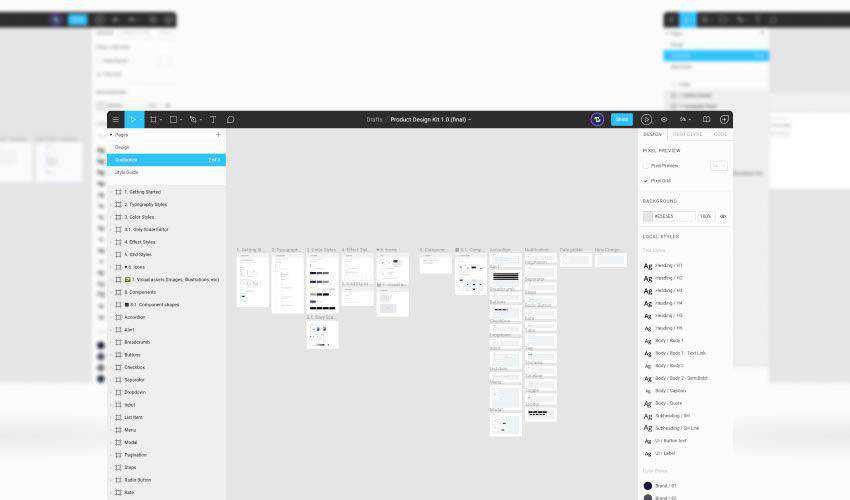

How to Install Layer Styles in Photoshop

- Open Photoshop: Launch the program.

- Locate the Layer Styles Panel: In Photoshop, you can find the Layer Styles panel within the Layer Style dialog box. Go to the

Layermenu, selectLayer Style, and chooseBlending Options. - Import Layer Styles: To install new layer styles, you’ll need to import them. Click on the specific layer effect that you want to add a new style to. A dialog box for that effect will appear. Here, you can adjust settings for the effect. At the top of the dialog box, you’ll find a small gear icon. Click on it, and from the dropdown menu, select

Import Styles. A file dialog box will open. Navigate to the location where you have the layer style file (usually with a.aslextension) saved, select it, and clickLoad. - New Layer Style: After loading the layer style, you should see it added to the list of styles within the Layer Style dialog box. It will be available for you to use on your layers.

How to Use Layer Styles in Photoshop

- Select a Layer: Choose the layer in your project to which you want to apply a layer style. You can do this by clicking on the layer in the Layers panel.

- Access Layer Styles: Once your layer is selected, go to the Layer Style dialog box,

Layermenu >Layer Style>Blending Options. - Apply a Layer Style: Within the Layer Style dialog box, you can enable and customize the layer styles you want to apply. Simply check the box next to the layer style you want to use, and it will be applied to your selected layer.

- Adjust Settings: Each layer style has its own set of settings that you can tweak to achieve the desired effect. Click on the name of the layer style to access its settings, and make adjustments as needed.

- Preview and Confirm: As you adjust the settings, you can preview the changes in real-time on your selected layer. Once satisfied with the result, click

OKto apply the layer style to your layer. - Save Your Work: Don’t forget to save your project to keep the applied layer styles intact.

Use Layer Styles in Photoshop Today!

These Photoshop layer styles for text effects allow you to add depth, dimension, and visual interest to your text designs.

With a range of customizable effects in your toolbox – and because of their ease of application – layer styles are an essential resource for creating eye-catching and dynamic text effects in your design projects.