Iccha Sethi is Vice President of Engineering at Vanta, the leading Trust Management Platform, where she leads initiatives focused on enhancing security and compliance automation. Previously, she was an engineering leader at GitHub where she oversaw a multi-product portfolio including Actions, Hosted Runners, Codespaces, Packages, Pages,…

TransAgents: A New Approach to Machine Translation for Literary Works

Translating literary classics like War and Peace into other languages often results in losing the author’s unique style and cultural nuances. Addressing this longstanding challenge in literary translation is essential to preserving the essence of works while making them accessible globally. TransAgents introduces a pioneering approach…

PTZOptics Empowering Courtrooms with Live Streaming & Video Capture – Videoguys

In an era where digital integration has become paramount, PTZOptics stands at the forefront of providing innovative solutions for various sectors, notably within the courtroom. PTZOptics PTZ cameras, known for their expansive coverage, remote control features, and excellent optical zoom capabilities, have consistently proved to be ideal tools for modernizing traditionally large and challenging environments. Through an assortment of case studies, they aim to showcase how our technology has made a positive impact in various judiciary applications across the United States.

|

Transforming Courtrooms with PTZ Technology In an age of technological advancement, courtrooms across the nation are embracing PTZ (pan, tilt, zoom) technology to revolutionize the legal experience. By integrating PTZ cameras, courtrooms are able to ensure comprehensive coverage of proceedings with minimal manpower. This not only enhances efficiency but also fosters greater accessibility and transparency. Whether live-streaming for remote viewing or archiving for future reference, PTZ technology is setting a new standard for justice in the digital era, aligning the judicial system with modern needs and expectations. |

[embedded content] |

|

Fixed Cameras PTZOptics offers a range of fixed cameras called “ZCams” that provide a cost-effective solution for capturing high-quality video of specific areas within the courtroom. These cameras are designed to remain stationary while delivering excellent video coverage, making them ideal for recording proceedings, ensuring transparency, and maintaining a reliable video record without the need for frequent adjustments. |

|

Manage Your Spaces Seamlessly with Hive

|

|

| [embedded content] |

|

With our courtroom management system, ensure that your IT and AV teams have the tools they need to keep the judicial process running smoothly and efficiently. Experience the peace of mind that comes with knowing you have complete control over your courtroom technology, all from a single, powerful interface.

|

[embedded content] |

|

NDAA Compliance Select PTZOptics cameras comply with NDAA 2019, Section 889, ensuring they do not contain components from restricted companies. This compliance is crucial for organizations that prioritize security and adhere to federal regulations. For more information, please refer to the camera documentation. |

Courtroom Video Systems

PTZ cameras enable seamless communication within governmental agencies, from local meetings to global summits, fostering collaboration and decision-making. Learn how top local, state and federal court systems are upgrading their video systems.

Ensuring Transparency

With live streaming and video recording capabilities, PTZOptics empowers judiciaries to maintain transparency with their constituents. Our technology ensures that proceedings are accessible to the public, promoting trust, integrity, and responsiveness in public administration.

|

Pioneering Courtroom Modernization In the pursuit of justice, adaptability, and accessibility, PTZOptics has been instrumental in modernizing courtroom video systems across the United States. Below is a remarkable case study that stands as a testament to our impact. |

[embedded content] |

|

PTZOptics Cameras The city of Whitefish embraced PTZOptics cameras to redefine its courtroom experience. These state-of-the-art cameras, known for their expansive coverage and discreet in-room mounting locations, have provided a seamless and efficient solution to handle large spaces. This integration not only enhances functionality but also promotes greater accessibility to judicial proceedings. |

|

PTZOptics cameras are often chosen for government applications such as courtrooms due to their large size. These spaces can benefit from the remote control and optical zoom features available on PTZOptics cameras. In this case study, the city of Whitefish, Montana approved the installation for four PTZOptics cameras to be used with a vMix video switching system. The cameras are installed in remote locations to the video production studio allowing a single camera operator to control the pan, tilt and zoom of each camera. Each camera is set up with camera presets that are assigned to various areas of interest inside the courtroom. |

PTZ Cameras For Legal Proceedings

|

|

PTZ Camera in Ceiling at City Hall |

|

New York State Unified Court System’s Digital Transformation The New York State Unified Court System (NYS UCS), serving as the judicial branch of the state government, has embarked on an ambitious modernization journey to make its 1,540 courtrooms more functional, accessible, and equipped for the digital era. The Courtroom Modernization Initiative (CMI) Team was established in 2019 to actualize this vision; PTZOptics played a pivotal role in the transition along with other key vendors, such as Magewell and Biamp. |

Learn more about PTZOptics here:

Clever Polypane Debugging Features I’m Loving

I’m working on a refresh of my personal website, what I’m calling the HD remaster. Well, I wouldn’t call it a “full” redesign. I’m just cleaning things up, and Polypane is coming in clutch. I wrote about how much …

Clever Polypane Debugging Features I’m Loving originally…

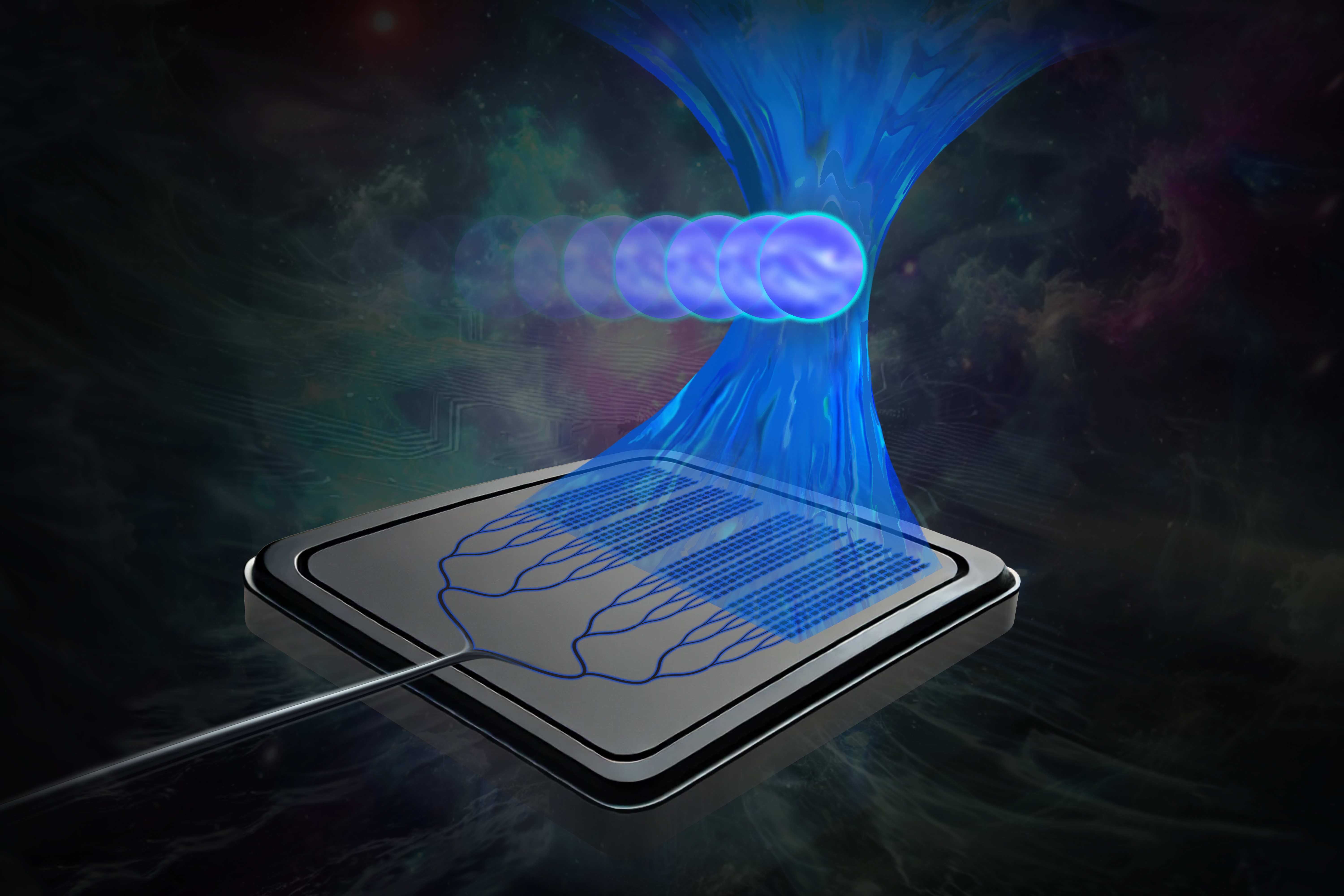

MIT engineers create a chip-based tractor beam for biological particles

MIT researchers have developed a miniature, chip-based “tractor beam,” like the one that captures the Millennium Falcon in the film “Star Wars,” that could someday help biologists and clinicians study DNA, classify cells, and investigate the mechanisms of disease.

Small enough to fit in the palm of your hand, the device uses a beam of light emitted by a silicon-photonics chip to manipulate particles millimeters away from the chip surface. The light can penetrate the glass cover slips that protect samples used in biological experiments, enabling cells to remain in a sterile environment.

Traditional optical tweezers, which trap and manipulate particles using light, usually require bulky microscope setups, but chip-based optical tweezers could offer a more compact, mass manufacturable, broadly accessible, and high-throughput solution for optical manipulation in biological experiments.

However, other similar integrated optical tweezers can only capture and manipulate cells that are very close to or directly on the chip surface. This contaminates the chip and can stress the cells, limiting compatibility with standard biological experiments.

Using a system called an integrated optical phased array, the MIT researchers have developed a new modality for integrated optical tweezers that enables trapping and tweezing of cells more than a hundred times further away from the chip surface.

“This work opens up new possibilities for chip-based optical tweezers by enabling trapping and tweezing of cells at much larger distances than previously demonstrated. It’s exciting to think about the different applications that could be enabled by this technology,” says Jelena Notaros, the Robert J. Shillman Career Development Professor in Electrical Engineering and Computer Science (EECS), and a member of the Research Laboratory of Electronics.

Joining Notaros on the paper are lead author and EECS graduate student Tal Sneh; Sabrina Corsetti, an EECS graduate student; Milica Notaros PhD ’23; Kruthika Kikkeri PhD ’24; and Joel Voldman, the William R. Brody Professor of EECS. The research appears today in Nature Communications.

A new trapping modality

Optical traps and tweezers use a focused beam of light to capture and manipulate tiny particles. The forces exerted by the beam will pull microparticles toward the intensely focused light in the center, capturing them. By steering the beam of light, researchers can pull the microparticles along with it, enabling them to manipulate tiny objects using noncontact forces.

However, optical tweezers traditionally require a large microscope setup in a lab, as well as multiple devices to form and control light, which limits where and how they can be utilized.

“With silicon photonics, we can take this large, typically lab-scale system and integrate it onto a chip. This presents a great solution for biologists, since it provides them with optical trapping and tweezing functionality without the overhead of a complicated bulk-optical setup,” Notaros says.

But so far, chip-based optical tweezers have only been capable of emitting light very close to the chip surface, so these prior devices could only capture particles a few microns off the chip surface. Biological specimens are typically held in sterile environments using glass cover slips that are about 150 microns thick, so the only way to manipulate them with such a chip is to take the cells out and place them on its surface.

However, that leads to chip contamination. Every time a new experiment is done, the chip has to be thrown away and the cells need to be put onto a new chip.

To overcome these challenges, the MIT researchers developed a silicon photonics chip that emits a beam of light that focuses about 5 millimeters above its surface. This way, they can capture and manipulate biological particles that remain inside a sterile cover slip, protecting both the chip and particles from contamination.

Manipulating light

The researchers accomplish this using a system called an integrated optical phased array. This technology involves a series of microscale antennas fabricated on a chip using semiconductor manufacturing processes. By electronically controlling the optical signal emitted by each antenna, researchers can shape and steer the beam of light emitted by the chip.

Motivated by long-range applications like lidar, most prior integrated optical phased arrays weren’t designed to generate the tightly focused beams needed for optical tweezing. The MIT team discovered that, by creating specific phase patterns for each antenna, they could form an intensely focused beam of light, which can be used for optical trapping and tweezing millimeters from the chip’s surface.

“No one had created silicon-photonics-based optical tweezers capable of trapping microparticles over a millimeter-scale distance before. This is an improvement of several orders of magnitude higher compared to prior demonstrations,” says Notaros.

By varying the wavelength of the optical signal that powers the chip, the researchers could steer the focused beam over a range larger than a millimeter and with microscale accuracy.

To test their device, the researchers started by trying to capture and manipulate tiny polystyrene spheres. Once they succeeded, they moved on to trapping and tweezing cancer cells provided by the Voldman group.

“There were many unique challenges that came up in the process of applying silicon photonics to biophysics,” Sneh adds.

The researchers had to determine how to track the motion of sample particles in a semiautomated fashion, ascertain the proper trap strength to hold the particles in place, and effectively postprocess data, for instance.

In the end, they were able to show the first cell experiments with single-beam optical tweezers.

Building off these results, the team hopes to refine the system to enable an adjustable focal height for the beam of light. They also want to apply the device to different biological systems and use multiple trap sites at the same time to manipulate biological particles in more complex ways.

“This is a very creative and important paper in many ways,” says Ben Miller, Dean’s Professor of Dermatology and professor of biochemistry and biophysics at the University of Rochester, who was not involved with this work. “For one, given that silicon photonic chips can be made at low cost, it potentially democratizes optical tweezing experiments. That may sound like something that only would be of interest to a few scientists, but in reality having these systems widely available will allow us to study fundamental problems in single-cell biophysics in ways previously only available to a few labs given the high cost and complexity of the instrumentation. I can also imagine many applications where one of these devices (or possibly an array of them) could be used to improve the sensitivity of disease diagnostic.”

This research is funded by the National Science Foundation (NSF), an MIT Frederick and Barbara Cronin Fellowship, and the MIT Rolf G. Locher Endowed Fellowship.

10 Best Employee Engagement Software Platforms (October 2024)

Many of today’s employee engagement platforms are leveraging artificial intelligence to improve how organizations connect with, develop, and retain their workforce. These AI-powered solutions are transforming traditional HR processes, offering unprecedented insights into employee sentiment, streamlining onboarding procedures, and personalizing learning and development initiatives. The integration…

Celebrating the people behind Kendall Square’s innovation ecosystem

While it’s easy to be amazed by the constant drumbeat of innovations coming from Kendall Square in Cambridge, Massachusetts, sometimes overlooked are the dedicated individuals working to make those scientific and technological breakthroughs a reality. Every day, people in the neighborhood tackle previously intractable problems and push the frontiers of their fields.

This year’s Kendall Square Association (KSA) Annual Meeting centered around celebrating the people behind the area’s prolific innovation ecosystem. That included a new slate of awards and recognitions for community members and a panel discussion featuring MIT President Sally Kornbluth.

“It’s truly inspiring to be surrounded by all of you: people who seem to share an exuberant curiosity, a pervasive ethic of service, and the baseline expectation that we’re all interested in impact — in making a difference for people and the planet,” Kornbluth said.

The gathering took place in MIT’s Walker Memorial (Building 50) on Memorial Drive and attracted entrepreneurs, life science workers, local students, restaurant and retail shop owners, and leaders of nonprofits.

The KSA itself is a nonprofit organization made up of over 150 organizations across the greater Kendall Square region, from large companies to universities like MIT and Harvard, along with the independent shops and restaurants that give Kendall Square its distinct character.

New to this year’s event were two Founder Awards, which were given to Sangeeta Bhatia, the the John and Dorothy Wilson Professor of Health Sciences and Technology and of Electrical Engineering and Computer Science at MIT, and Michal Preminger, head of Johnson and Johnson Innovation, for their work bringing people together to achieve hard things that benefit humanity.

The KSA will donate $2,500 to the Science Club for Girls in Bhatia’s honor and $2,500 to Innovators for Purpose in honor of Preminger.

Recognition was also given to Alex Cheung of the Cambridge Innovation Center and Shazia Mir of LabCentral for their work bringing Kendall Square’s community members together.

Cambridge Mayor Denise Simmons also spoke at the event, noting the vital role the Kendall Square community has played in things like Covid-19 vaccine development and in the fight against climate change.

“As many of you know, Cambridge has a long and proud history of innovation, with the presence of MIT and the remarkable growth of the tech and life science industry examples of that,” Simons said. “We are leaving a lasting, positive impact in our city. This community has made and continues to make enormous contributions, not just to our city but to the world.”

In her talk, Kornbluth also introduced the Kendall Square community to her plans for The Climate Project at MIT, which is designed to focus the Institute’s talent and resources to achieve real-world impact on climate change faster. The project will provide funding and catalyze partnerships around six climate “missions,” or broad areas where MIT researchers will seek to identify gaps in the global climate response that MIT can help fill.

“The Climate Project is a whole-of-MIT mobilization that’s mission driven, solution focused, and outward looking,” Kornbluth explained. “If you want to make progress, faster and at scale, that’s the way!”

After mingling with Kendall community members, Kornbluth said she still considers herself a newbie to the area but is coming to see the success of Kendall Square and MIT as more than a coincidence.

“The more time I spend here, the more I come to understand the incredible synergies between MIT and Kendall Square,” Kornbluth said. “We know, for example, that proximity is an essential ingredient in our collective and distinctive recipe for impact. That proximity, and the cross-fertilization that comes with it, helps us churn out new technologies and patents, found startups, and course-correct our work as we try to keep pace with the world’s challenges. We can’t do any of this separately. Our work together — all of us in this thriving, wildly entrepreneurial community — is what drives the success of our innovation ecosystem.”

How Microsoft’s TorchGeo Streamlines Geospatial Data for Machine Learning Experts

In today’s data-driven world, geospatial information is essential for gaining insights into climate change, urban growth, disaster management, and global security. Despite its vast potential, working with geospatial data presents significant challenges due to its size, complexity, and lack of standardization. Machine learning can analyze these…

Translating MIT research into real-world results

Inventive solutions to some of the world’s most critical problems are being discovered in labs, classrooms, and centers across MIT every day. Many of these solutions move from the lab to the commercial world with the help of over 85 Institute resources that comprise MIT’s robust innovation and entrepreneurship (I&E) ecosystem. The Abdul Latif Jameel Water and Food Systems Lab (J-WAFS) draws on MIT’s wealth of I&E knowledge and experience to help researchers commercialize their breakthrough technologies through the J-WAFS Solutions grant program. By collaborating with I&E programs on campus, J-WAFS prepares MIT researchers for the commercial world, where their novel innovations aim to improve productivity, accessibility, and sustainability of water and food systems, creating economic, environmental, and societal benefits along the way.

The J-WAFS Solutions program launched in 2015 with support from Community Jameel, an international organization that advances science and learning for communities to thrive. Since 2015, J-WAFS Solutions has supported 19 projects with one-year grants of up to $150,000, with some projects receiving renewal grants for a second year of support. Solutions projects all address challenges related to water or food. Modeled after the esteemed grant program of MIT’s Deshpande Center for Technological Innovation, and initially administered by Deshpande Center staff, the J-WAFS Solutions program follows a similar approach by supporting projects that have already completed the basic research and proof-of-concept phases. With technologies that are one to three years away from commercialization, grantees work on identifying their potential markets and learn to focus on how their technology can meet the needs of future customers.

“Ingenuity thrives at MIT, driving inventions that can be translated into real-world applications for widespread adoption, implantation, and use,” says J-WAFS Director Professor John H. Lienhard V. “But successful commercialization of MIT technology requires engineers to focus on many challenges beyond making the technology work. MIT’s I&E network offers a variety of programs that help researchers develop technology readiness, investigate markets, conduct customer discovery, and initiate product design and development,” Lienhard adds. “With this strong I&E framework, many J-WAFS Solutions teams have established startup companies by the completion of the grant. J-WAFS-supported technologies have had powerful, positive effects on human welfare. Together, the J-WAFS Solutions program and MIT’s I&E ecosystem demonstrate how academic research can evolve into business innovations that make a better world,” Lienhard says.

Creating I&E collaborations

In addition to support for furthering research, J-WAFS Solutions grants allow faculty, students, postdocs, and research staff to learn the fundamentals of how to transform their work into commercial products and companies. As part of the grant requirements, researchers must interact with mentors through MIT Venture Mentoring Service (VMS). VMS connects MIT entrepreneurs with teams of carefully selected professionals who provide free and confidential mentorship, guidance, and other services to help advance ideas into for-profit, for-benefit, or nonprofit ventures. Since 2000, VMS has mentored over 4,600 MIT entrepreneurs across all industries, through a dynamic and accomplished group of nearly 200 mentors who volunteer their time so that others may succeed. The mentors provide impartial and unbiased advice to members of the MIT community, including MIT alumni in the Boston area. J-WAFS Solutions teams have been guided by 21 mentors from numerous companies and nonprofits. Mentors often attend project events and progress meetings throughout the grant period.

“Working with VMS has provided me and my organization with a valuable sounding board for a range of topics, big and small,” says Eric Verploegen PhD ’08, former research engineer in MIT’s D-Lab and founder of J-WAFS spinout CoolVeg. Along with professors Leon Glicksman and Daniel Frey, Verploegen received a J-WAFS Solutions grant in 2021 to commercialize cold-storage chambers that use evaporative cooling to help farmers preserve fruits and vegetables in rural off-grid communities. Verploegen started CoolVeg in 2022 to increase access and adoption of open-source, evaporative cooling technologies through collaborations with businesses, research institutions, nongovernmental organizations, and government agencies. “Working as a solo founder at my nonprofit venture, it is always great to have avenues to get feedback on communications approaches, overall strategy, and operational issues that my mentors have experience with,” Verploegen says. Three years after the initial Solutions grant, one of the VMS mentors assigned to the evaporative cooling team still acts as a mentor to Verploegen today.

Another Solutions grant requirement is for teams to participate in the Spark program — a free, three-week course that provides an entry point for researchers to explore the potential value of their innovation. Spark is part of the National Science Foundation’s (NSF) Innovation Corps (I-Corps), which is an “immersive, entrepreneurial training program that facilitates the transformation of invention to impact.” In 2018, MIT received an award from the NSF, establishing the New England Regional Innovation Corps Node (NE I-Corps) to deliver I-Corps training to participants across New England. Trainings are open to researchers, engineers, scientists, and others who want to engage in a customer discovery process for their technology. Offered regularly throughout the year, the Spark course helps participants identify markets and explore customer needs in order to understand how their technologies can be positioned competitively in their target markets. They learn to assess barriers to adoption, as well as potential regulatory issues or other challenges to commercialization. NE-I-Corps reports that since its start, over 1,200 researchers from MIT have completed the program and have gone on to launch 175 ventures, raising over $3.3 billion in funding from grants and investors, and creating over 1,800 jobs.

Constantinos Katsimpouras, a research scientist in the Department of Chemical Engineering, went through the NE I-Corps Spark program to better understand the customer base for a technology he developed with professors Gregory Stephanopoulos and Anthony Sinskey. The group received a J-WAFS Solutions grant in 2021 for their microbial platform that converts food waste from the dairy industry into valuable products. “As a scientist with no prior experience in entrepreneurship, the program introduced me to important concepts and tools for conducting customer interviews and adopting a new mindset,” notes Katsimpouras. “Most importantly, it encouraged me to get out of the building and engage in interviews with potential customers and stakeholders, providing me with invaluable insights and a deeper understanding of my industry,” he adds. These interviews also helped connect the team with companies willing to provide resources to test and improve their technology — a critical step to the scale-up of any lab invention.

In the case of Professor Cem Tasan’s research group in the Department of Materials Science and Engineering, the I-Corps program led them to the J-WAFS Solutions grant, instead of the other way around. Tasan is currently working with postdoc Onur Guvenc on a J-WAFS Solutions project to manufacture formable sheet metal by consolidating steel scrap without melting, thereby reducing water use compared to traditional steel processing. Before applying for the Solutions grant, Guvenc took part in NE I-Corps. Like Katsimpouras, Guvenc benefited from the interaction with industry. “This program required me to step out of the lab and engage with potential customers, allowing me to learn about their immediate challenges and test my initial assumptions about the market,” Guvenc recalls. “My interviews with industry professionals also made me aware of the connection between water consumption and steelmaking processes, which ultimately led to the J-WAFS 2023 Solutions Grant,” says Guvenc.

After completing the Spark program, participants may be eligible to apply for the Fusion program, which provides microgrants of up to $1,500 to conduct further customer discovery. The Fusion program is self-paced, requiring teams to conduct 12 additional customer interviews and craft a final presentation summarizing their key learnings. Professor Patrick Doyle’s J-WAFS Solutions team completed the Spark and Fusion programs at MIT. Most recently, their team was accepted to join the NSF I-Corps National program with a $50,000 award. The intensive program requires teams to complete an additional 100 customer discovery interviews over seven weeks. Located in the Department of Chemical Engineering, the Doyle lab is working on a sustainable microparticle hydrogel system to rapidly remove micropollutants from water. The team’s focus has expanded to higher value purifications in amino acid and biopharmaceutical manufacturing applications. Devashish Gokhale PhD ’24 worked with Doyle on much of the underlying science.

“Our platform technology could potentially be used for selective separations in very diverse market segments, ranging from individual consumers to large industries and government bodies with varied use-cases,” Gokhale explains. He goes on to say, “The I-Corps Spark program added significant value by providing me with an effective framework to approach this problem … I was assigned a mentor who provided critical feedback, teaching me how to formulate effective questions and identify promising opportunities.” Gokhale says that by the end of Spark, the team was able to identify the best target markets for their products. He also says that the program provided valuable seminars on topics like intellectual property, which was helpful in subsequent discussions the team had with MIT’s Technology Licensing Office.

Another member of Doyle’s team, Arjav Shah, a recent PhD from MIT’s Department of Chemical Engineering and a current MBA candidate at the MIT Sloan School of Management, is spearheading the team’s commercialization plans. Shah attended Fusion last fall and hopes to lead efforts to incorporate a startup company called hydroGel. “I admire the hypothesis-driven approach of the I-Corps program,” says Shah. “It has enabled us to identify our customers’ biggest pain points, which will hopefully lead us to finding a product-market fit.” He adds “based on our learnings from the program, we have been able to pivot to impact-driven, higher-value applications in the food processing and biopharmaceutical industries.” Postdoc Luca Mazzaferro will lead the technical team at hydroGel alongside Shah.

In a different project, Qinmin Zheng, a postdoc in the Department of Civil and Environmental Engineering, is working with Professor Andrew Whittle and Lecturer Fábio Duarte. Zheng plans to take the Fusion course this fall to advance their J-WAFS Solutions project that aims to commercialize a novel sensor to quantify the relative abundance of major algal species and provide early detection of harmful algal blooms. After completing Spark, Zheng says he’s “excited to participate in the Fusion program, and potentially the National I-Corps program, to further explore market opportunities and minimize risks in our future product development.”

Economic and societal benefits

Commercializing technologies developed at MIT is one of the ways J-WAFS helps ensure that MIT research advances will have real-world impacts in water and food systems. Since its inception, the J-WAFS Solutions program has awarded 28 grants (including renewals), which have supported 19 projects that address a wide range of global water and food challenges. The program has distributed over $4 million to 24 professors, 11 research staff, 15 postdocs, and 30 students across MIT. Nearly half of all J-WAFS Solutions projects have resulted in spinout companies or commercialized products, including eight companies to date plus two open-source technologies.

Nona Technologies is an example of a J-WAFS spinout that is helping the world by developing new approaches to produce freshwater for drinking. Desalination — the process of removing salts from seawater — typically requires a large-scale technology called reverse osmosis. But Nona created a desalination device that can work in remote off-grid locations. By separating salt and bacteria from water using electric current through a process called ion concentration polarization (ICP), their technology also reduces overall energy consumption. The novel method was developed by Jongyoon Han, professor of electrical engineering and biological engineering, and research scientist Junghyo Yoon. Along with Bruce Crawford, a Sloan MBA alum, Han and Yoon created Nona Technologies to bring their lightweight, energy-efficient desalination technology to the market.

“My feeling early on was that once you have technology, commercialization will take care of itself,” admits Crawford. The team completed both the Spark and Fusion programs and quickly realized that much more work would be required. “Even in our first 24 interviews, we learned that the two first markets we envisioned would not be viable in the near term, and we also got our first hints at the beachhead we ultimately selected,” says Crawford. Nona Technologies has since won MIT’s $100K Entrepreneurship Competition, received media attention from outlets like Newsweek and Fortune, and hired a team that continues to further the technology for deployment in resource-limited areas where clean drinking water may be scarce.

Food-borne diseases sicken millions of people worldwide each year, but J-WAFS researchers are addressing this issue by integrating molecular engineering, nanotechnology, and artificial intelligence to revolutionize food pathogen testing. Professors Tim Swager and Alexander Klibanov, of the Department of Chemistry, were awarded one of the first J-WAFS Solutions grants for their sensor that targets food safety pathogens. The sensor uses specialized droplets that behave like a dynamic lens, changing in the presence of target bacteria in order to detect dangerous bacterial contamination in food. In 2018, Swager launched Xibus Systems Inc. to bring the sensor to market and advance food safety for greater public health, sustainability, and economic security.

“Our involvement with the J-WAFS Solutions Program has been vital,” says Swager. “It has provided us with a bridge between the academic world and the business world and allowed us to perform more detailed work to create a usable application,” he adds. In 2022, Xibus developed a product called XiSafe, which enables the detection of contaminants like salmonella and listeria faster and with higher sensitivity than other food testing products. The innovation could save food processors billions of dollars worldwide and prevent thousands of food-borne fatalities annually.

J-WAFS Solutions companies have raised nearly $66 million in venture capital and other funding. Just this past June, J-WAFS spinout SiTration announced that it raised an $11.8 million seed round. Jeffrey Grossman, a professor in MIT’s Department of Materials Science and Engineering, was another early J-WAFS Solutions grantee for his work on low-cost energy-efficient filters for desalination. The project enabled the development of nanoporous membranes and resulted in two spinout companies, Via Separations and SiTration. SiTration was co-founded by Brendan Smith PhD ’18, who was a part of the original J-WAFS team. Smith is CEO of the company and has overseen the advancement of the membrane technology, which has gone on to reduce cost and resource consumption in industrial wastewater treatment, advanced manufacturing, and resource extraction of materials such as lithium, cobalt, and nickel from recycled electric vehicle batteries. The company also recently announced that it is working with the mining company Rio Tinto to handle harmful wastewater generated at mines.

But it’s not just J-WAFS spinout companies that are producing real-world results. Products like the ECC Vial — a portable, low-cost method for E. coli detection in water — have been brought to the market and helped thousands of people. The test kit was developed by MIT D-Lab Lecturer Susan Murcott and Professor Jeffrey Ravel of the MIT History Section. The duo received a J-WAFS Solutions grant in 2018 to promote safely managed drinking water and improved public health in Nepal, where it is difficult to identify which wells are contaminated by E. coli. By the end of their grant period, the team had manufactured approximately 3,200 units, of which 2,350 were distributed — enough to help 12,000 people in Nepal. The researchers also trained local Nepalese on best manufacturing practices.

“It’s very important, in my life experience, to follow your dream and to serve others,” says Murcott. Economic success is important to the health of any venture, whether it’s a company or a product, but equally important is the social impact — a philosophy that J-WAFS research strives to uphold. “Do something because it’s worth doing and because it changes people’s lives and saves lives,” Murcott adds.

As J-WAFS prepares to celebrate its 10th anniversary this year, we look forward to continued collaboration with MIT’s many I&E programs to advance knowledge and develop solutions that will have tangible effects on the world’s water and food systems.

Learn more about the J-WAFS Solutions program and about innovation and entrepreneurship at MIT.

3 Questions: Bridging anthropology and engineering for clean energy in Mongolia

In 2021, Michael Short, an associate professor of nuclear science and engineering, approached professor of anthropology Manduhai Buyandelger with an unusual pitch: collaborating on a project to prototype a molten salt heat bank in Mongolia, Buyandelger’s country of origin and place of her scholarship. It was also an invitation to forge a novel partnership between two disciplines that rarely overlap. Developed in collaboration with the National University of Mongolia (NUM), the device was built to provide heat for people in colder climates, and in places where clean energy is a challenge.

Buyandelger and Short teamed up to launch Anthro-Engineering Decarbonization at the Million-Person Scale, an initiative intended to advance the heat bank idea in Mongolia, and ultimately demonstrate its potential as a scalable clean heat source in comparably challenging sites around the world. This project received funding from the inaugural MIT Climate and Sustainability Consortium Seed Awards program. In order to fund various components of the project, especially student involvement and additional staff, the project also received support from the MIT Global Seed Fund, New Engineering Education Transformation (NEET), Experiential Learning Office, Vice Provost for International Activities, and d’Arbeloff Fund for Excellence in Education.

As part of this initiative, the partners developed a special topic course in anthropology to teach MIT undergraduates about Mongolia’s unique energy and climate challenges, as well as the historical, social, and economic context in which the heat bank would ideally find a place. The class 21A.S01 (Anthro-Engineering: Decarbonization at the Million-Person Scale) prepares MIT students for a January Independent Activities Period (IAP) trip to the Mongolian capital of Ulaanbaatar, where they embed with Mongolian families, conduct research, and collaborate with their peers. Mongolian students also engaged in the project. Anthropology research scientist and lecturer Lauren Bonilla, who has spent the past two decades working in Mongolia, joined to co-teach the class and lead the IAP trips to Mongolia.

With the project now in its third year and yielding some promising solutions on the ground, Buyandelger and Bonilla reflect on the challenges for anthropologists of advancing a clean energy technology in a developing nation with a unique history, politics, and culture.

Q: Your roles in the molten salt heat bank project mark departures from your typical academic routine. How did you first approach this venture?

Buyandelger: As an anthropologist of contemporary religion, politics, and gender in Mongolia, I have had little contact with the hard sciences or building or prototyping technology. What I do best is listening to people and working with narratives. When I first learned about this device for off-the-grid heating, a host of issues came straight to mind right away that are based on socioeconomic and cultural context of the place. The salt brick, which is encased in steel, must be heated to 400 degrees Celsius in a central facility, then driven to people’s homes. Transportation is difficult in Ulaanbaatar, and I worried about road safety when driving the salt brick to gers [traditional Mongolian homes] where many residents live. The device seemed a bit utopian to me, but I realized that this was an amazing educational opportunity: We could use the heat bank as part of an ethnographic project, so students could learn about the everyday lives of people — crucially, in the dead of winter — and how they might respond to this new energy technology in the neighborhoods of Ulaanbaatar.

Bonilla: When I first went to Mongolia in the early 2000s as an undergraduate student, the impacts of climate change were already being felt. There had been a massive migration to the capital after a series of terrible weather events that devastated the rural economy. Coal mining had emerged as a vital part of the economy, and I was interested in how people regarded this industry that both provided jobs and damaged the air they breathed. I am trained as a human geographer, which involves seeing how things happening in a local place correspond to things happening at a global scale. Thinking about climate or sustainability from this perspective means making linkages between social life and environmental life. In Mongolia, people associated coal with national progress. Based on historical experience, they had low expectations for interventions brought by outsiders to improve their lives. So my first take on the molten salt project was that this was no silver bullet solution. At the same time, I wanted to see how we could make this a great project-based learning experience for students, getting them to think about the kind of research necessary to see if some version of the molten salt would work.

Q: After two years, what lessons have you and the students drawn from both the class and the Ulaanbaatar field trips?

Buyandelger: We wanted to make sure MIT students would not go to Mongolia and act like consultants. We taught them anthropological methods so they could understand the experiences of real people and think about how to bring people and new technologies together. The students, from engineering and anthropological and social science backgrounds, became critical thinkers who could analyze how people live in ger districts. When they stay with families in Ulaanbaatar in January, they not only experience the cold and the pollution, but they observe what people do for work, how parents care for their children, how they cook, sleep, and get from one place to another. This enables them to better imagine and test out how these people might utilize the molten salt heat bank in their homes.

Bonilla: In class, students learn that interventions like this often fail because the implementation process doesn’t work, or the technology doesn’t meet people’s real needs. This is where anthropology is so important, because it opens up the wider landscape in which you’re intervening. We had really difficult conversations about the professional socialization of engineers and social scientists. Engineers love to work within boxes, but don’t necessarily appreciate the context in which their invention will serve.

As a group, we discussed the provocative notion that engineers construct and anthropologists deconstruct. This makes it seem as if engineers are creators, and anthropologists are brought in as add-ons to consult and critique engineers’ creations. Our group conversation concluded that a project such as ours benefits from an iterative back-and-forth between the techno-scientific and humanistic disciplines.

Q: So where does the molten salt brick project stand?

Bonilla: Our research in Mongolia helped us produce a prototype that can work: Our partners at NUM are developing a hybrid stove that incorporates the molten salt brick. Supervised by instructor Nathan Melenbrink of MIT’s NEET program, our engineering students have been involved in this prototyping as well.

The concept is for a family to heat it up using a coal fire once a day and it warms their home overnight. Based on our anthropological research, we believe that this stove would work better than the device as originally conceived. It won’t eliminate coal use in residences, but it will reduce emissions enough to have a meaningful impact on ger districts in Ulaanbaatar. The challenge now is getting funding to NUM so they can test different salt combinations and stove models and employ local blacksmiths to work on the design.

This integrated stove/heat bank will not be the ultimate solution to the heating and pollution crisis in Mongolia. But it will be something that can inspire even more ideas. We feel with this project we are planting all kinds of seeds that will germinate in ways we cannot anticipate. It has sparked new relationships between MIT and Mongolian students, and catalyzed engineers to integrate a more humanistic, anthropological perspective in their work.

Buyandelger: Our work illustrates the importance of anthropology in responding to the unpredictable and diverse impacts of climate change. Without our ethnographic research — based on participant observation and interviews, led by Dr. Bonilla, — it would have been impossible to see how the prototyping and modifications could be done, and where the molten salt brick could work and what shape it needed to take. This project demonstrates how indispensable anthropology is in moving engineering out of labs and companies and directly into communities.

Bonilla: This is where the real solutions for climate change are going to come from. Even though we need solutions quickly, it will also take time for new technologies like molten salt bricks to take root and grow. We don’t know where the outcomes of these experiments will take us. But there’s so much that’s emerging from this project that I feel very hopeful about.