Mass spectrometers, devices that identify chemical substances, are widely used in applications like crime scene analysis, toxicology testing, and geological surveying. But these machines are bulky, expensive, and easy to damage, which limits where they can be effectively deployed.

Using additive manufacturing, MIT researchers produced a mass filter, which is the core component of a mass spectrometer, that is far lighter and cheaper than the same type of filter made with traditional techniques and materials.

Their miniaturized filter, known as a quadrupole, can be completely fabricated in a matter of hours for a few dollars. The 3D-printed device is as precise as some commercial-grade mass filters that can cost more than $100,000 and take weeks to manufacture.

Built from durable and heat-resistant glass-ceramic resin, the filter is 3D printed in one step, so no assembly is required. Assembly often introduces defects that can hamper the performance of quadrupoles.

This lightweight, cheap, yet precise quadrupole is one important step in Luis Fernando Velásquez-García’s 20-year quest to produce a 3D-printed, portable mass spectrometer.

“We are not the first ones to try to do this. But we are the first ones who succeeded at doing this. There are other miniaturized quadrupole filters, but they are not comparable with professional-grade mass filters. There are a lot of possibilities for this hardware if the size and cost could be smaller without adversely affecting the performance,” says Velásquez-García, a principal research scientist in MIT’s Microsystems Technology Laboratories (MTL) and senior author of a paper detailing the miniaturized quadrupole.

For instance, a scientist could bring a portable mass spectrometer to remote areas of the rainforest, using it to rapidly analyze potential pollutants without shipping samples back to a lab. And a lightweight device would be cheaper and easier to send into space, where it could monitor chemicals in Earth’s atmosphere or on those of distant planets.

Velásquez-García is joined on the paper by lead author Colin Eckhoff, an MIT graduate student in electrical engineering and computer science (EECS); Nicholas Lubinsky, a former MIT postdoc; and Luke Metzler and Randall Pedder of Ardara Technologies. The research is published in Advanced Science.

Size matters

At the heart of a mass spectrometer is the mass filter. This component uses electric or magnetic fields to sort charged particles based on their mass-to-charge ratio. In this way, the device can measure the chemical components in a sample to identify an unknown substance.

A quadrupole, a common type of mass filter, is composed of four metallic rods surrounding an axis. Voltages are applied to the rods, which produce an electromagnetic field. Depending on the properties of the electromagnetic field, ions with a specific mass-to-charge ratio will swirl around through the middle of the filter, while other particles escape out the sides. By varying the mix of voltages, one can target ions with different mass-to-charge ratios.

While fairly simple in design, a typical stainless-steel quadrupole might weigh several kilograms. But miniaturizing a quadrupole is no easy task. Making the filter smaller usually introduces errors during the manufacturing process. Plus, smaller filters collect fewer ions, which makes chemical analysis less sensitive.

“You can’t make quadrupoles arbitrarily smaller — there is a tradeoff,” Velásquez-García adds.

His team balanced this tradeoff by leveraging additive manufacturing to make miniaturized quadrupoles with the ideal size and shape to maximize precision and sensitivity.

They fabricate the filter from a glass-ceramic resin, which is a relatively new printable material that can withstand temperatures up to 900 degrees Celsius and performs well in a vacuum.

The device is produced using vat photopolymerization, a process where a piston pushes into a vat of liquid resin until it nearly touches an array of LEDs at the bottom. These illuminate, curing the resin that remains in the minuscule gap between the piston and the LEDs. A tiny layer of cured polymer is then stuck to the piston, which rises up and repeats the cycle, building the device one tiny layer at a time.

“This is a relatively new technology for printing ceramics that allows you to make very precise 3D objects. And one key advantage of additive manufacturing is that you can aggressively iterate the designs,” Velásquez-García says.

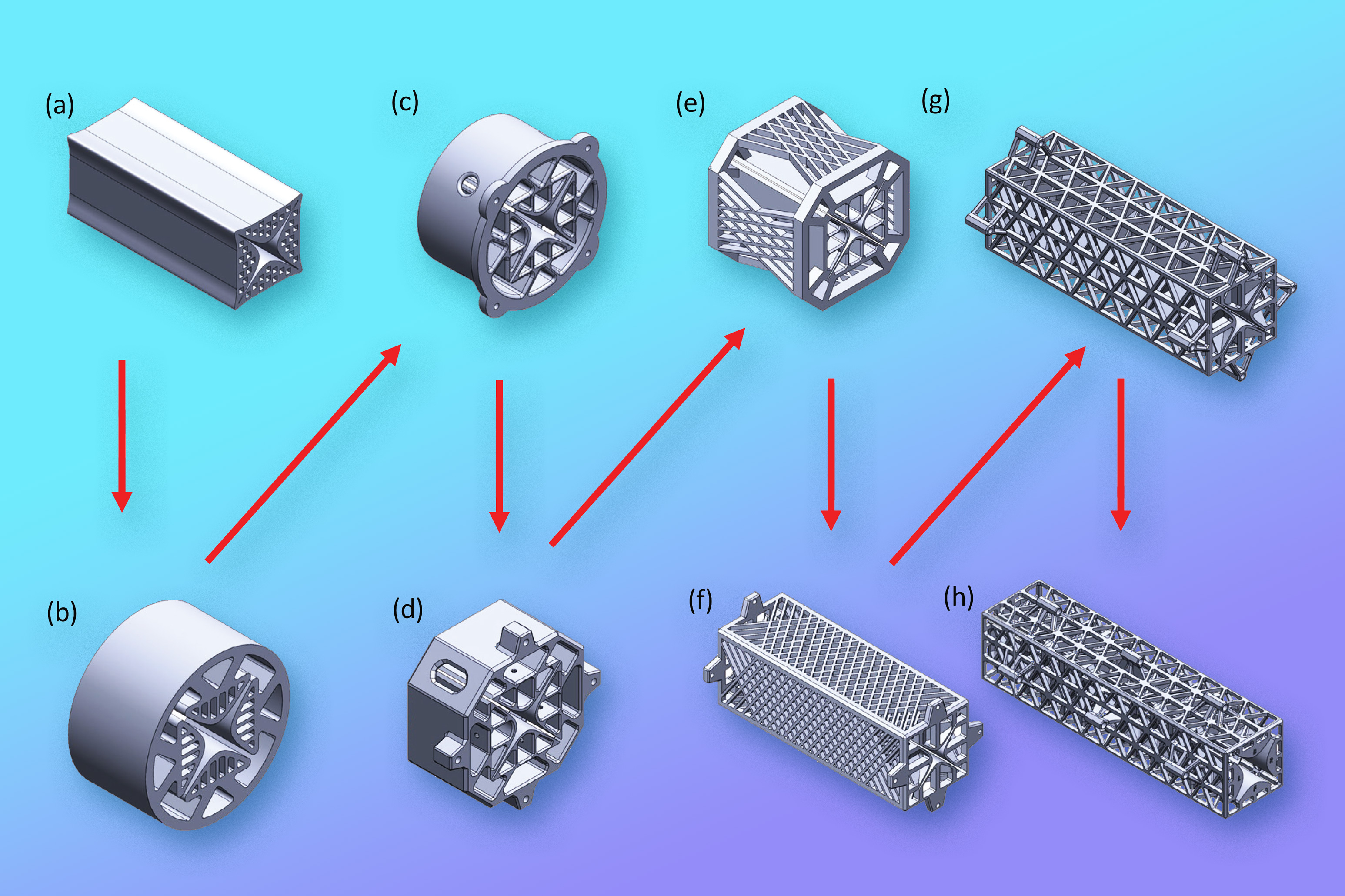

Since the 3D printer can form practically any shape, the researchers designed a quadrupole with hyperbolic rods. This shape is ideal for mass filtering but difficult to make with conventional methods. Many commercial filters employ rounded rods instead, which can reduce performance.

They also printed an intricate network of triangular lattices surrounding the rods, which provides durability while ensuring the rods remain positioned correctly if the device is moved or shaken.

To finish the quadrupole, the researchers used a technique called electroless plating to coat the rods with a thin metal film, which makes them electrically conductive. They cover everything but the rods with a masking chemical and then submerge the quadrupole in a chemical bath heated to a precise temperature and stirring conditions. This deposits a thin metal film on the rods uniformly without damaging the rest of the device or shorting the rods.

“In the end, we made quadrupoles that were the most compact but also the most precise that could be made, given the constraints of our 3D printer,” Velásquez-García says.

Maximizing performance

To test their 3D-printed quadrupoles, the team swapped them into a commercial system and found that they could attain higher resolutions than other types of miniature filters. Their quadrupoles, which are about 12 centimeters in length, are one-quarter the density of comparable stainless-steel filters.

In addition, further experiments suggest that their 3D-printed quadrupoles could achieve precision that is on par with that of largescale commercial filters.

“Mass spectrometry is one of the most important of all scientific tools, and Velásquez-Garcia and co-workers describe the design, construction, and performance of a quadrupole mass filter that has several advantages over earlier devices,” says Graham Cooks, the Henry Bohn Hass Distinguished Professor of Chemistry in the Aston Laboratories for Mass Spectrometry at Purdue University, who was not involved with this work. “The advantages derive from these facts: It is much smaller and lighter than most commercial counterparts and it is fabricated monolithically, using additive construction. … It is an open question as to how well the performance will compare with that of quadrupole ion traps, which depend on the same electric fields for mass measurement but which do not have the stringent geometrical requirements of quadrupole mass filters.”

“This paper represents a real advance in the manufacture of quadrupole mass filters (QMF). The authors bring together their knowledge of manufacture using advanced materials, QMF drive electronics, and mass spectrometry to produce a novel system with good performance at low cost,” adds Steve Taylor, professor of electrical engineering and electronics at the University of Liverpool, who was also not involved with this paper. “Since QMFs are at the heart of the ‘analytical engine’ in many other types of mass spectrometry systems, the paper has an important significance across the whole mass spectrometry field, which worldwide represents a multibillion-dollar industry.”

In the future, the researchers plan to boost the quadrupole’s performance by making the filters longer. A longer filter can enable more precise measurements since more ions that are supposed to be filtered out will escape as the chemical travels along its length. They also intend to explore different ceramic materials that could better transfer heat.

“Our vision is to make a mass spectrometer where all the key components can be 3D printed, contributing to a device with much less weight and cost without sacrificing performance. There is still a lot of work to do, but this is a great start,” Velásquez-Garcia adds.

This work was funded by Empiriko Corporation.